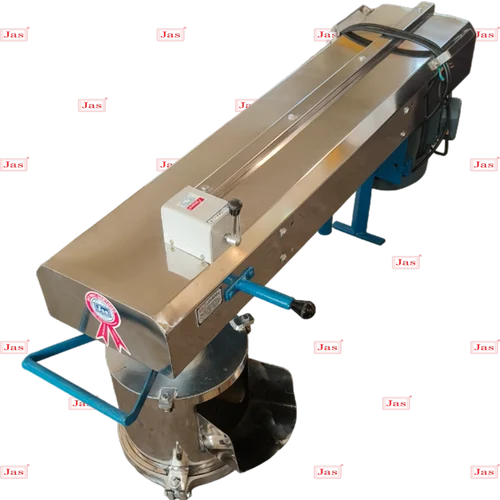

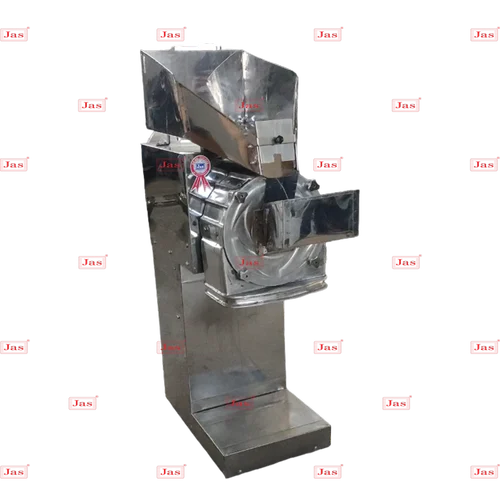

Potato Chips Making Machines

Price:

₹ 5000 /Piece (pc)

| Capacity | 1000 kg per hour |

| Usage/Application | Potato Chips |

| Frequency | 50 Hz |

| Machine Type | Semi-Automatic |

| Machine Components | Washing or Peeling & Cutting |

| Input Voltage V | 110 -440 volts |

| Automatic Grade | Semi-Automatic, Automatic |

| Power Consumption | 0-2 HP |

| Country of Origin | Made in India |

Jas enterprise is specializing in manufacturing and export of super grade potato chips making machines ( Automatic) that are in wide demand in the global marketplace. Commercial potato chips machine is made from heavy duty stainless steel fabricated body. Adjustable stainless steel blades are fitted on aluminum die. Chips slicing die is rotated by suitable electric motor. Base of chips machine is made from mild steel angle and covered with stainless steel sheet. Stainless steel easily detachable hopper is supplied with these potato chips making machines.

Key features of potato chips machine:-

- Unique and reliable design

- The potato chips machines are highly effective as well as nonstop continuous slicing process.

- Stainless steel shaft the aluminum die have stainless steel thickness adjustable blades and it can easily remove grids, assuring hygiene cleaning.

- All contacting parts are stainless steel, aluminum no corrosion hazards.

- Increased production leading to faster return on the investments due to quality and design.

- All rotating parts are dynamic balanced for less vibration & higher performances.

Standard accessories of potato chips machine:-

- Suitable 4 pole totally enclosed fan cooled single or three phase sq. Cage motor as per is: 325 or 996 is supplied with vegetable cutter {electricity (special power can be accommodated): 110/220/380/415 volts, 50/60 Hz, 1/3 phase}

- Two numbers of blades (one number for slicing, one number for sali chips which are most of all use for farali chivda)

Extra accessories of chips machine

- Suitable miniature circuit breaker as per is: 8828 for over load protraction of electric motor.

- Starters, main switch, ampere meter, capacitor for single phase electric motor.

- Potato Peeler

- Potato chips dewatering machine

- Fryer

- Oil Extractor

About Jas Enterprises Service perfection, quality superiority, and ever-resting research and development are the core enterprise spirits of JAS. Responding to both customer and international market demands, we never stop innovating for machine function and quality improvement, accompanied by accurate and in-time after-service. To improve quality control, JAS has been certified with ISO 9001. To speed up our service, We assist our customers not only with hardware, like parts and maintenance but also with software, like recipe consultant. Quality-assured tailor-made machines tagged with reasonable prices have earned JAS a good reputation and have established JAS as a well-known Indian leading brand. Till 2023, JAS has successfully exported to the USA, Canada, UK, Sri Lanka, Nepal, Bhutan, Burma, and many African, countries. To increase production efficiency, quality, and R&D duration, JAS will relocate to our newly completed factory buildings at Bakrol before 2020 ends. We are ready to provide you with a better and faster service experience. Since 1990, Mr. Sheth set JAS’s vision to become the most professional ethnic food machine manufacturer in the world. JAS thus enhanced the RD team to design food equipment for Middle and South America, East Europe, Middle East, Gulf countries, South-East Asia, Africa, etc. To expand production capacity, Mr. Sheth set up 2 other sister concern companies, Techno Agencies, and Khasiyat Masala Machines, to fabricate parts and basic assembly. Future Visions To design the most efficient production flow that can supply machines in the shortest time. To provide engineering staff with a working environment that can bring out their creativity. To develop a professional production line research team that focuses on an in-depth exploration of production and machine technology to enhance the durability of the machines. To establish strict quality control processing and testing methods. To create an industry-leading engineering team. Core Value Concentrate on JAS’s core value as a “Professional machine manufacturer and service provider for traditional foods” Ever-resting innovation and R&D The customer is our partner Fair profit sharing Tailor-made machine customization Complete horizontally integrated supply chain for a comprehensive turnkey project Quality Policy JAS’s quality policy is to ensure perfect service, excellent quality, and never-ending R&D innovations. For our clients worldwide, JAS does the very best to provide excellent food machinery and its related services to strengthen our long-term mutually beneficial partnership. JAS concentrates equal enthusiasm on every aspect of our company to establish the enterprise culture of service perfection, quality superiority, and never-ending research, development and improvement. We aim to provide clients with comprehensive satisfaction. JAS carefully selects prime part suppliers for quality assurance. We promise to keep improving every tiny aspect in our process to present superior machines and service to our clients. ISO quality policy is thoroughly carried out in JAS. Meanwhile, ERP, PDM and other management systems are applied to complete material and process management. Competitive Advantages 1. Superior quality with reasonable prices: JAS is ISO 9001 certified, quality assured, and priced reasonably. Machine specifications are customized to fit international markets and customer demands. 2. Tailor made to client requirements: JAS suggests suitable machines per each customer’s product requirements. Machine frame bases, functional parts, and mold modifications, and customizations are also available for each client’s special demands. For example, JAS’s best-seller, the Multi-Purpose Snack Making Machine, Jas-PMM-600 not only has hundreds of standard and special shape die for reference, but still fabricates more and more dies for each client’s specific product recipe, size, weight, and shape for JAS’s client only. Client satisfaction is JAS’s main goal. 3. Supply recipes that are suitable for JAS machines: Since 1990, JAS has successfully developed many recipes accepted by international markets. Detailed start-up recipes are also included in our machine and service packages for client reference. 4. Timely response and follow-up service: JAS will respond to customer phone calls, e-mails, or faxes for machinery or production problems within 24 hours to prevent a client’s potential loss. Now we have also included WhatsApp as a mode of communication on a trial basis. 5. Fully equipped test kitchen: In our test kitchen, a wide range of flours, food additives, seasonings, fillings, and relative processing machines such as mixers, vegetable cutters, hydro extractors, steamers, baking ovens, as well as other cooking devices are ready for on-site client testing to ensure the machine fits each client’s final product requirements. 6. The Widest product range available and the soundest specifications selectable. 7. Available for both the semi-automatic production line and turn-key project: In response to the rise of emerging markets, JAS has developed semi-automatic production lines at lower investment capitals to process primary agricultural products into higher value-added foods with longer shelf lives or baked, fried, or cooked snacks. We can also customize high-capacity automatic production lines for clients. In addition to factory planning, raw material processing, production line planning, production process optimization, and new product development, JAS can also integrate other related quality reputed and cost-reasonable Indian suppliers to complete the turn-key project for you. Through single contact windows, JAS handles order placing, machine inspecting, crating, and commissioning as well as after-sales servicing all together for clients to prevent hassles from placing orders separately and to drastically save clients the shipping costs, import document expenses, inland transportation, and the commissioning costs from respective suppliers. After-sales service to be conducted by only JAS will ensure the clients face no issues and concerns regarding communication and maintenance capability so that clients can receive timely responses and fast parts. 8. Successfully Exported worldwide: Since 1990, JAS has successfully exported its machines worldwide. With many practical experiences, JAS can provide clients with the most effective market information and customer service experience. 9. Complete parts safety stock for all machine series: Except for special parts, we can deliver the components each client needs right away. 10. Professional R&D team: Our specialized R&D teams are constantly developing new machines, effectively fabricating tailor-made machines, and working to improve machine quality. 11. Complete market information: JAS never stops doing market surveys & attending international exhibitions. With decades of knowledge accumulated about market information and changes in food trends, we can provide the most valuable information to our clients, and assist our clients in industrial upgrading. 12. Help customers make money: JAS’s machines are reasonably priced, high in capacity, and superior in quality and function. With capabilities to produce value-added products, JAS’s machines are sure to roll client’s investments back in a short amount of time and constantly make a profit for clients. Company Structure Sales Department Responsibility Our sales Department is a customer-oriented, customer-focused vanguard of JAS, composed of a group of enthusiastic, professional sales, marketing, and shipping personnel who handle the selling, marketing, and customer service. Department features Professional sales divisions: These divisions are responsible for individual teams that carry out root-down market and food trend understanding. Join international exhibitions every year for market exploration. Be each client’s consultant: whether a client has mechanical or recipe questions, JAS will respond in time for their satisfaction. Advanced Internet marketing team: The internet marketing team is responsible for maintaining JAS websites and internet marketing strategy executions to always keep JAS on the front line of new information. Future visions To provide clients with ever-improving service. Continuously research and bond with market trends, and actively explore emerging markets. Optimize JAS website information so that each client can find accurate information he or she needs. Management department Responsibility Recruit and retain the most suitable personnel Train staff on expertise and leadership. Maintain and operate IT systems. Provide JAS staff with a positive, healthy, and efficient working environment. Department features Diverse work challenges and rewards staff with a sense of accomplishment. Be a strategic partner in enterprise development and provide value-added services for the company by improving organizational and individual capabilities. Future visions Provide JAS staff with the best service and become their trustworthy partner. Dedicated to creating a happy working environment for JAS staff to unleash their creativity and full potential. Sound internal service is the foundation for JAS to provide clients with service satisfaction and perfection. Research and development department Department Responsibility Develop new machines in response to new market demands. Research different food specialties to expand the database for future machine and recipe development. Develop and design customized machines per client requirements. Upgrade machine functions and mechanisms. Department features The professional team applies advanced hardware and software to develop precise designs. The PDM management system is applied to track designs and issues of different machine models and versions for best know-how management. With the assistance of 3D rapid prototype printing technology, results according to user requirements will be quickly rendered and presented for customer satisfaction. An active atmosphere and comfortable work environment will unleash R&D personnel’s maximum creativity potential. Future visions To become the pioneer for global ethnic food machines, research, and development. To become a comprehensive R&D team from recipes and production processes to machinery. Engineering department Responsibility Arrange machine production schedules and carefully control production quality. Assist in machine customization and development as well as other related matters. Effectively control machine production costs. Take responsibility for warehouse affairs, safety, and the parts stock control. Thoroughly carry out quality control work for the goods flow. Department features Site flow process and production line planning all follow 5S site management method specifications. Production flows are based on ISO guidelines with clear record tracks. Implementation of creative management to effectively put colleagues’ imaginations and creativity into practice so that product quality continues across the bottleneck. Implementation of education outreach so that new employees can learn relevant technical knowledge effectively to avoid technical faults. Production units are divided by machine similarity specialties into different groups to effectively make the production and maintenance service more professional and specialized. Implementation of abnormal product quality correction system, so that clients get immediate response and service. Department units from production management, procurement, and quality assurance to warehouse and production are integrated into the flow line to achieve the ultimate production efficiency. As well as making batch productions, the production line is also capable of making customized machines in order to provide full servicing. All engineers are required to pass an annual professional review to ensure that the best quality service is provided to clients. Headquarters Introduction JAS enterprise has always been committed to environmental protection, energy saving, and carbon reduction. The green building concept has been applied to the construction of the new company building. JAS’s new plant construction is planned and designed based on the green building concept. The building materials and landscape designs are green and environmentally friendly to carbon reduction targets. The office areas and the factory’s interior spaces are decorated with landscapes and images of trees and flowers to give JAS staff an impression of working in a green, safe, and comfortable environment. The building materials are not only environmentally friendly but also embody an aesthetically and artistically humanistic atmosphere. Black and gray tiles scattered on the exterior wall resemble a natural flambé glaze style which symbolizes the fresh and humble JAS enterprise image. Architectural concrete is the other major theme of our building exterior which gives a fresh impression of minimal simplicity. Sales Service Fast customer response: All inquiries are replied to in detail within 72 hours of being received by JAS. Professional sales engineers: Every engineer understands the operation and maintenance of the machines, as well as the food production processes and formulations. If a customer has a problem, a JAS sales engineer will discuss the characteristics of the mechanics and products with customers to come up with the best solution. Standardized pilot testing services: Before delivery, JAS engineers inspect and test the machines in accordance with customer demand. Fine-tuning is done to make sure the product meets customer requirements better. Wood crate packaging: Meeting international standards, the packaging will protect the machine from damage during transit. Detailed machine operation manual: JAS will enclose the detailed machine operation manual with each machine to let clients understand the operation steps and notifications. Diversified ways of customer training: Machine commissioning can be processed either on the client’s site or taught at our experience center. The commissioning process can also be filmed for customers’ easy access to become familiar with the machine operating.

Legal Status of Entity

Jas EnterprisesEstablishment

1990Business Type

GST

24AMMPS0980M1ZGNumber of Employees

50Working Days

Monday, Wednesday, Thursday, Friday, Saturday, Sunday