ATE MIG-400D MIG Welding Machine, 20-400A

Price:

₹ 58000 /Piece (pc)

Asit Sinha

Plot NO.A 12, Eurocity Industrial, H Block, Auto Cluster

Member Since: 0.7 years

GST: 27AAICA0433A1ZD

Visit StoreATE MIG-400D MIG Welding Machine, 20-400A

Product Details:

| Brand | ATE |

| Model | MIG-400D |

| Welding Current Range | 20-400A |

| Power Consumption | 14 kVA |

| Phase | 3 Phase |

| Working Voltage | 440 +- 15%V |

| Power Factor | 0.93 |

| Efficiency | 0.85 |

| Technology | IGBT |

| Protection Class | IP 21 |

| Weight | 145 kg |

| Dimension (L x B x H) | 650 x 408 x 756 mm |

| Wire Feeding Speed | 3-15 m/min |

| Duty Cycle | 60% |

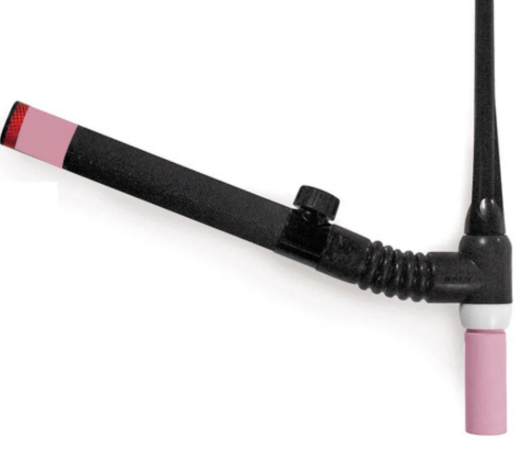

The MIG welding process is semi-automated. This is also called as Gas Metal Arc Welding (GMAW). The process of MIG welding was developed in 1940. As this is a semi-automated process so there is a constant supply of filler wire in the form of MIG wire. This wire is being supplied by wire feeder which has a motorized function. The wire passed through the liner which also has a gas feeding through the same cable to the point where an arc is formed. The MIG welding is used in fabrication where higher production is required. The process needs electricity to produce heat, electrode or filler wire for the joint and inert gas to protect the welding joint from the air in the form of an inert gas of Co2. We ask you to buy MIG welder and if a robot is used in this welding process this welding becomes automatic. This MIG welding process is fast, cost effective and produces more welding units in a small period of time so it is a more effective method of welding.

The types of wire used are Carbon steel, stainless steel, and Aluminium. The wire feeder needs special change for the Aluminium wire filler. The carbon steel is best suited for the MIG welding. The welding by MIG are as welding is clean without smoke, very cheap, fast, time-saving in changing of the electrode is minimum so time efficient. It is good for spot and tack welds

Other Details :

| Attribute | Model | |||

| MIG 400 D | MIG 600 D | MIG 400 T | MIG 600 T | |

| Input power Voltage | AC 440 V (3phase) ± 15%, 50/60 | AC 440 V (3phase) ± 15%, 50/60 | AC 440 V (3phase) ± 15%, 50/60 | AC 440 V (3phase) ± 15%, 50/60 |

| Rated input power capacity (KVA) | 14 | 35 | 12 | 32 |

| Output current ranges (A) | 20-400 | 20-600 | 20-400 | 20-600 |

| Rated output voltage (V) | 31.5 | 39 | 31.5 | 39 |

| Duty Cycle (%) | 60 | 60 | 60 | 60 |

| Weight (kgs) | 145 | 175 | 130 | 190 |

| Overall Dimensions (mm) | 650x408x756 | 776x436x814 | 680x408x756 | 710x436x814 |

| Protection Class | IP21 | IP21 | IP21 | IP21 |

| Wire feeder Speed (m/min) | 3-15 | 3-15 | 3-15 | 3-15 |

| Efficiency | 85 | 85 | 85 | 85 |

| Diameter of coil (mm) | 0.8-1.2 | 1.2-1.6 | 0.8-1.2 | 1.2-1.6 |

Additional Information:

- Port of Dispatch: Pune, India

- Production Capacity: As per requirement

- Delivery Time: Between 1 to 6 weeks depending on order quantity

- Packaging Details: Custom, as per requirements

Company Brief We, Ate Welding Engineering Robotics & Automation Private Limited from 1995 are one of the famous manufacturers, wholesalers, importers, exporters, and retailers a wide array of Welding Accessories. Our offered range consists of best grade Plasma Cutting Machines, Manual Metal ARC Welding Transformers and Welding Machines. This range is precisely manufactured using the best quality raw material and contemporary technology under the guidance of skilled professionals in compliance with the set quality standards. Also, our products are highly admired for their features such as robust construction, high strength, dimensional accuracy, excellent performance and longer service life. As per the requirements of the customers, this offered welding accessories can be customized and used in various applications like pre-engineered building, systems railways, pipes, aluminum fabrications and stainless steel fabrication. Spread over a large area of land, we have established a huge infrastructure facility that is known for carrying out standardized operations. By segmenting our infrastructure into various units, we ensure that all the on-going processes are carried out in the most streamlined way. Under the valuable guidance of, "Mr. Arunabh Majumdar", we have been able to meet exact requirements of clients in the most efficient manner. His sharp business acumen and rich industry knowledge help us to evolve as an eminent name in the industry. Basic Information Nature of Business Manufacturer Additional Business Factory / Manufacturing Company CEO Asit Sinha Key Customers Tata Group, Jamshedpur, Lucknow Larsen and Toubro Limited, Mumbai, Gujarat TVS Group, Pune, Chennai Registered Address Plot No. A-12, H Block, M. I. D. C. Pimpri, Pune- 411 018, Maharashtra, India Industry Welding Machines Total Number of Employees 11 to 25 People GST Registration Date 01-07-2017 Standards & Quality Certifications SSI Registration number : 323077461436 Legal Status of Firm Private Limited Company Proprietor Name Mr. Asit Sinha Annual Turnover 1.5 - 5 Cr

Legal Status of Entity

ATE WELDING ENGINEERING ROBOTICS AND AUTOMATION PRIVATE LIMITEDEstablishment

2017Business Type

GST

27AAICA0433A1ZDNumber of Employees

25Working Days

Monday to Saturday